Our Ultra-Light Experience

Access & Lightweight Solutions

- Access & Lightweight Solutions

When your project requires an ultra-light solution, we offer a product line of aluminum modular items. Yes, each individual item can be hand-carried! The rigid lattice structure makes these items ideal for light weight lifting and engineered scaffold alternatives resulting in significant time savings.

01

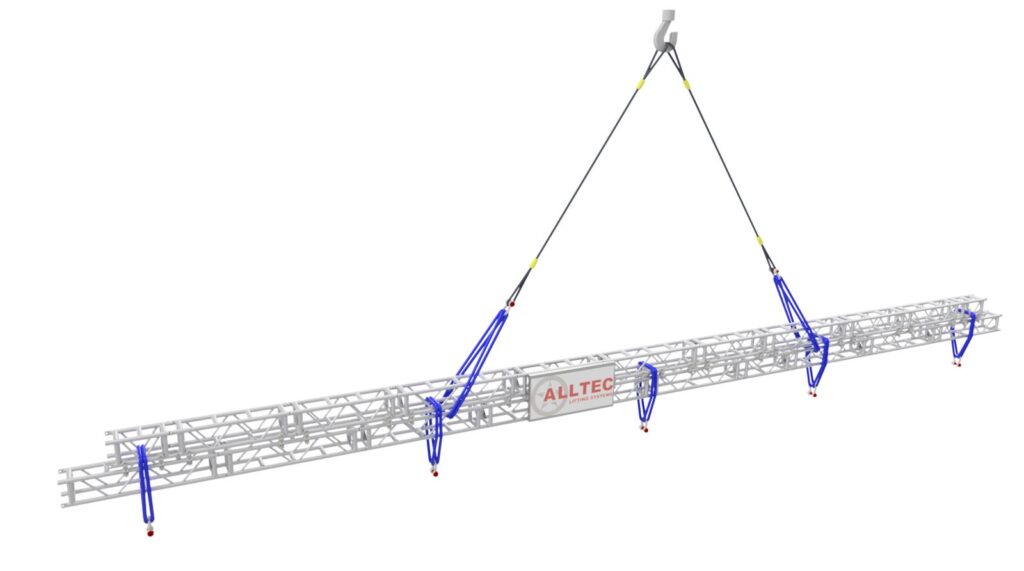

Lightweight Aluminum Lifting Beams

Alltec’s lightweight aluminum spreader makes lifting easier when weight matters, as even the heaviest piece is easy to carry by hand. Its simple, connect-the-dots design lets you build many different lifting setups quickly without any tools.

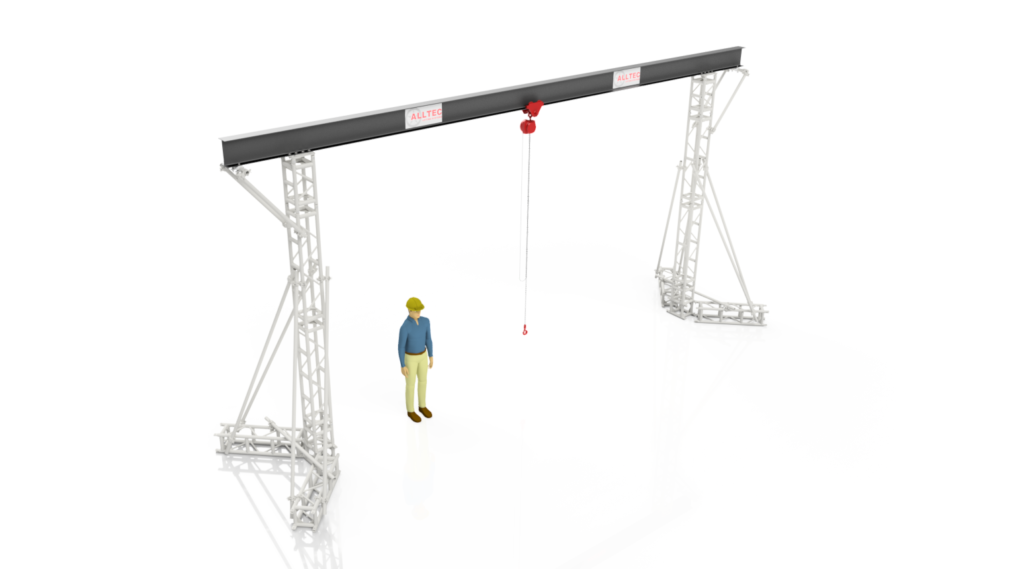

02

Aluminum Truss Gantry

Our aluminum truss gantry systems are designed to be lightweight and adaptable for various lifting jobs. Their modular design allows for different setups, and the aluminum parts are easy to carry and assemble quickly by hand.

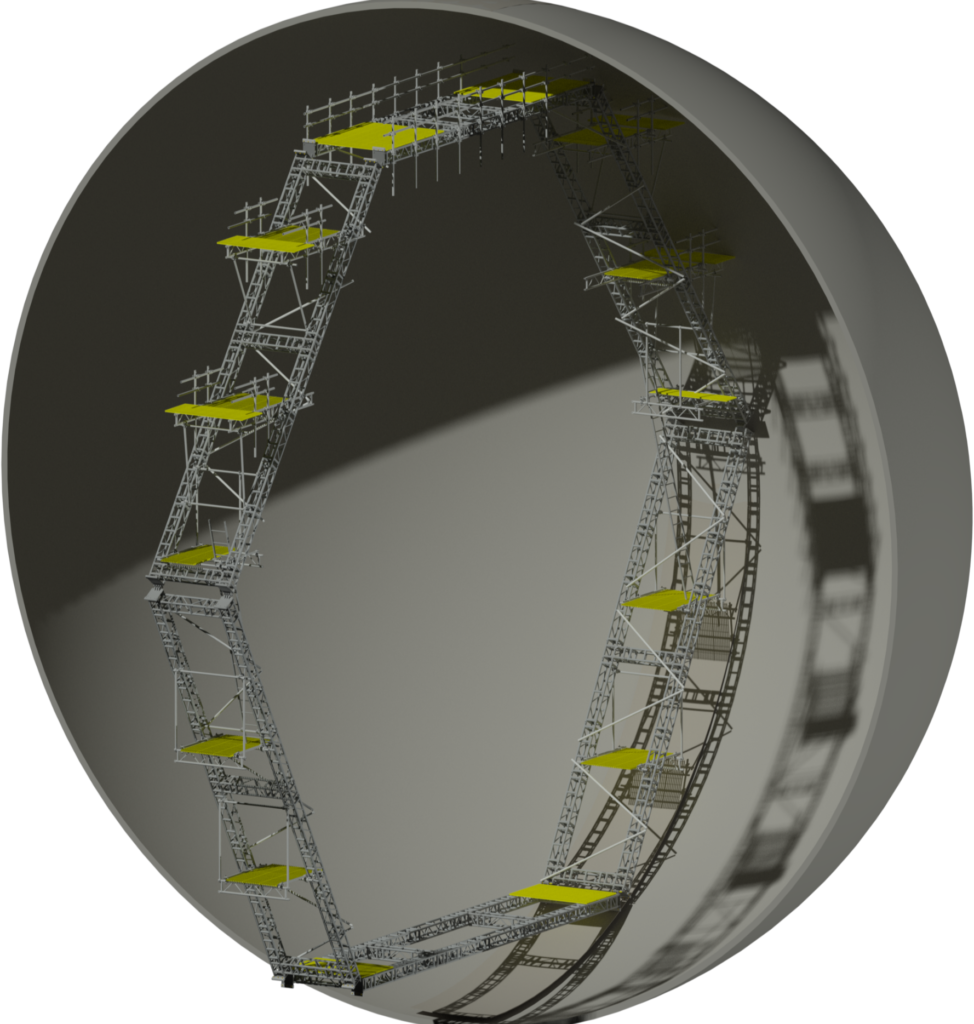

03

SPhere Access System

Our access systems significantly reduce project downtime and provide complete, safe access throughout tanks without any blind spots. Their modular, lightweight design meets safety standards, improves visibility and movement, and boosts overall productivity in confined spaces.

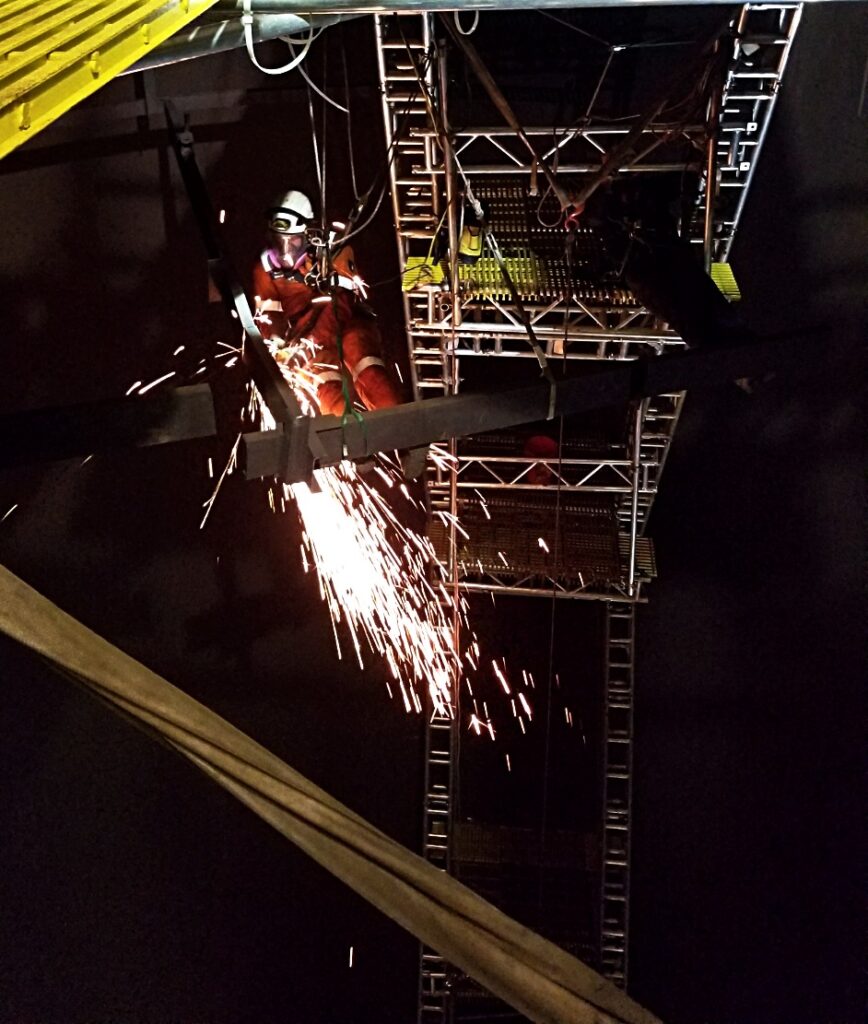

04

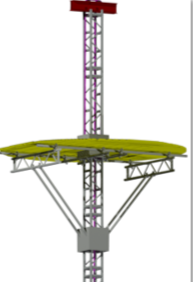

Upright Vessel Access System

Alltec’s adaptable aluminum lattice system offers a faster alternative to traditional scaffolding for vessel access. Its lightweight, hand-carryable parts fit through manholes and allow for complete 360-degree access at each level, with platforms that can be adjusted for obstructions.

- Lightweight Aluminum Lifting Beams

Alltec aluminum lattice spreader is designed and built to provide solutions to lifting operations when weight is of the essence. With the heaviest spreader component being only 43Lbs all components can be hand-carried.

The lattice design creates a rigid structure with exceptional bending and compression structural properties. Due to its modular design endless configurations can be built and because all connections are pinned-connections there is no need for power-tools to reconfigure. Past projects include spreader bar assemblies of up to 60ft with 6 pick points. Contact Alltec to learn more about the capabilities.

- Lightweight design

- Hand-carryable

- Modular

- Tool-free

- Aluminum Truss Gantry

Our modular lightweight gantry systems are available to accommodate and adapt to your lifting needs. Each configuration is engineered specifically to meet your lifting requirements; capacities vary per configurations.

The benefits of an aluminum truss gantry system are:

- Modular construction enables many different configurations

- All aluminum components can be hand carried and can easily go up/down and elevator/staircase

- Low pounds per square foot (psf) due to optimal load distribution and ultra light tare weight

- Simple and fast on-site assembly/disassembly

- Sphere Access System

Our proven access systems have cut previous clients project downtime by as much as 80%. Once erected, you will have 100% accessibility to any location in the tank with zero blind spots. From a safety standpoint, the system is safer than traditional access methods due to increased visibility, reduced risks associated with confined space, and ease of movement which also improves productivity.

- Meets ANSI A10.8 scaffolding requirements

- 5,000 lbs OSHA anchor point safety

- Adjustable work platforms

- Lightweight modular construction

- Decreased downtime with increased productivity

- Easy access and clear visibility

- Same Sphere, Two Methods

48′ Sphere was previously cleaned/inspected utilizing conventional scaffolding. Later, the same sphere was cleaned/inspected utilizing the Alltec Sphere Access System. The savings in man hours, decrease in downtime and less risk is apparent in the comparison below.

- Time Savings over traditional Scaffolding

- Assembly: 26 Days Saved

- Cleaning: Approx. 10 Days

- Dissaembly: 27 Days

- Total (Approx): 60 Days

- Upright Vessel Access Systems

Alltec engineering has developed endless applications for the modular aluminum lattice sections. The upright vessel access system presents an alternative to conventional scaffolding. The system can be installed at a fraction of the time compared to conventional scaffolding and provides 360 degrees access at each elevation. The individual components can be hand-carried and fit through a manhole. The platform can easily be partially folded in or removed to work around internal obstructions.